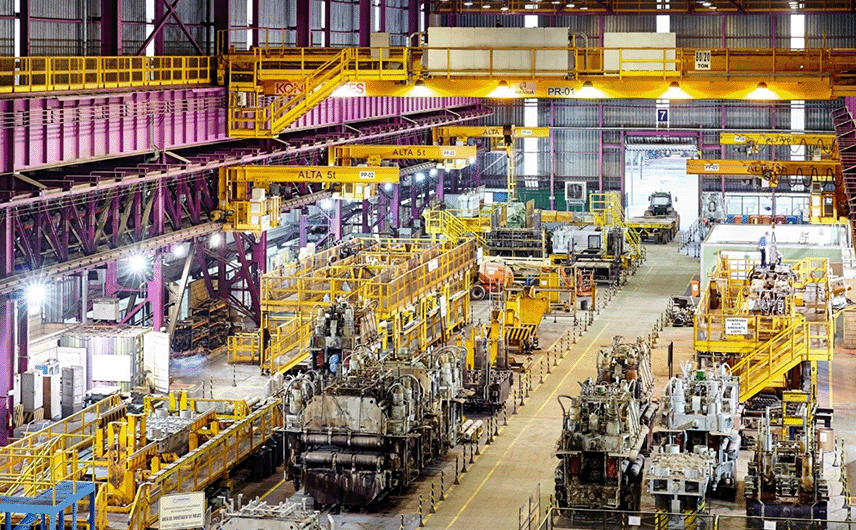

For the customer TERNIUM CSA / Brazil, Primetals Technologies is delivering on a 15-year service contract for mechanical and E&A maintenance. Aside from setting up maintenance facilities, Primetals Technologies also trained 600 maintenance employees.

Today offline maintenance for continuous casting machinery guarantees to improve the reliability of more than 100 critical components and enhance the product quality with fewer product downgrades. Higher product yield due to tighter tolerances of production equipment is key to ensure more uptime, higher productivity and reduced overall maintenance costs due to longer component lifetime and longer intervals between repairs, which results in lower expenditures for the customer of Primetals Technologies.

Adding value through digitalization

rimetals Technologies partnered with BOOM to develop MAT and enable Primetals Customers and own workshops to transform maintenance management processes into a competitive advantage.

Michael Weinzinger

With the need to get more and more digital and automate processes to direct the resources to the activities that add the most value, BOOM and Primetals Technologies agreed to cooperate in developing a “Metals Layer” based on the BMM – BOOM Maintenance Manager from then on called MAT – Maintenance and Asset Technology MAT allows Primetals Technologies to generate and compile know how to work smarter instead of working physically harder.

In that case, we are the suitable partner to achieve this goal.

Receive our latest newsletters directly to your inbox!