"In the keyboard of maintenance management, most companies only play on one or two octaves, but don't use the full potential."

Prof. Dr. Hubert Biedermann

In cooperation with Boom Software, the groundbreaking concept was transferred into a software solution which, thanks to its modular structure, makes it much easier for companies to get started with the LSM philosophy. With the Boom Maintenance Manager, Boom Software has developed a solution specifically for the manufacturing industry which, in accordance with the company’s mission statement “First in total Customizing”, is adapted to the specific requirements of the respective company and at the same time relies on already established and proven standards.

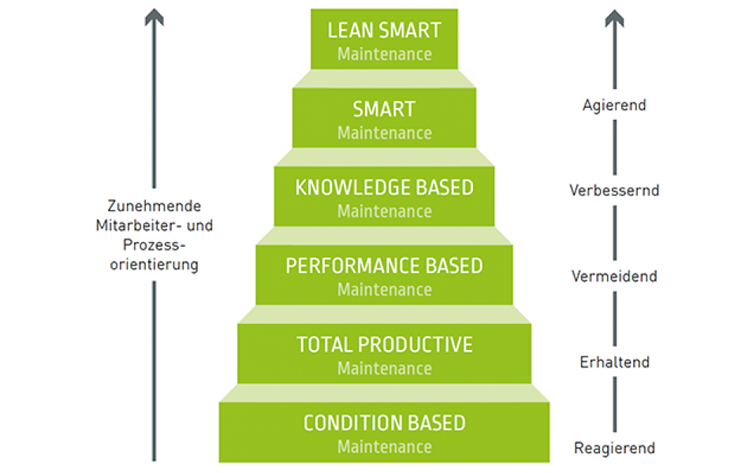

Most European industrial companies are only in the middle of the maintenance pyramid, which reflects the level of maturity of the maintenance strategy. To make a company fit for the future, it is necessary to break away from old reactive strategies and focus on proactive maintenance of the critical infrastructure, which is at the heart of the LSM concept.

The maintenance pyramid can be used to identify the maturity of a company’s maintenance strategy. This results in possible ways of dynamically adapting the strategy.

According to Prof. Biedermann, even large, well-known companies are still a long way from the ideal type of lean and smart data-driven maintenance. “You can only reach the last two levels of the maintenance pyramid when you overcome the digitalization barrier. Only then do you get to knowledge- and learning-based maintenance.”

The basic prerequisite for reorienting maintenance management towards LSM is a detailed assessment of the criticality of assets and components. With the Criticality & Asset Priority module (CAP), companies have a simple solution to evaluate their assets according to specific criteria.

The advantages at a glance:

Maintenance pursues the goal of managing everything that influences the probability of breakdowns on the one hand and keeping the direct effects of breakdowns as low as possible on the other. This risk can be easily captured with the criticality tool. In the first step, our experts, together with the company’s internal specialists, look at what the company’s success factors are (e.g. costs and plant availability) and, derived from this, the risk factors that jeopardize these goals are recorded in a risk assessment.

The Boom Maintenance Manager (BMM) displays the criticality value of each asset and component. Based on this asset classification, maintainers can accurately plan and argue measures.

The Boom Maintenance Manager makes it possible to automatically import quantitative data into the system and to access a pool of standardized qualitative criteria, which can be adapted to the specific needs of your company. The result is an overview of all assets and a graphically displayed portfolio that can be used to easily manage asset prioritization. This module can be used completely autonomously and represents the entry into LSM.

In the priority portfolio, assets and components are sorted according to their criticality. This facilitates the prioritization of maintenance measures.

You want to take the step towards LSM and are looking for a partner who can support you with competence and experience? We have already accompanied several companies on this path. Contact us, we will be pleased to help you!

Receive our latest newsletters directly to your inbox!