Maintenance management faces the challenge of ensuring availability of 750 facilities and optimally coordinating up to 6,000 maintenance tasks per year, a challenge that can be superbly mastered with a customized IPSA system.

36 maintenance employees at Lohmann-koester are tasked with maintaining production as each facility is individually supervised.

BMM provides a central system in which planning and documentation are depicted in a consistent and transparent manner. Faults and associated planning changes are comprehensible at any time. Thus, the focus of activities is on time and cost-effective maintenance planning. The goal of maintenance is to operate in a future-oriented manner while creating as much added value as possible.

BMM enriches our work at all maintenance levels and supports us in performing tasks efficiently and transparently. Several expansion projects are currently being planned, which will implement further functional modules in preparation for LEAN SMART MAINTENANCE. Material management and mobile maintenance are on our agenda."

Jan Neumann

One system for all maintenance measures

Obsolete maintenance software and a repair database based on MS Access were the predecessors of BMM. These legacy systems were no longer able to fulfill current requirements due to their age, insufficient range of functions and large data volumes. The flexibility and extensive spectrum of functions of BMM convinced Lohmann-koester.

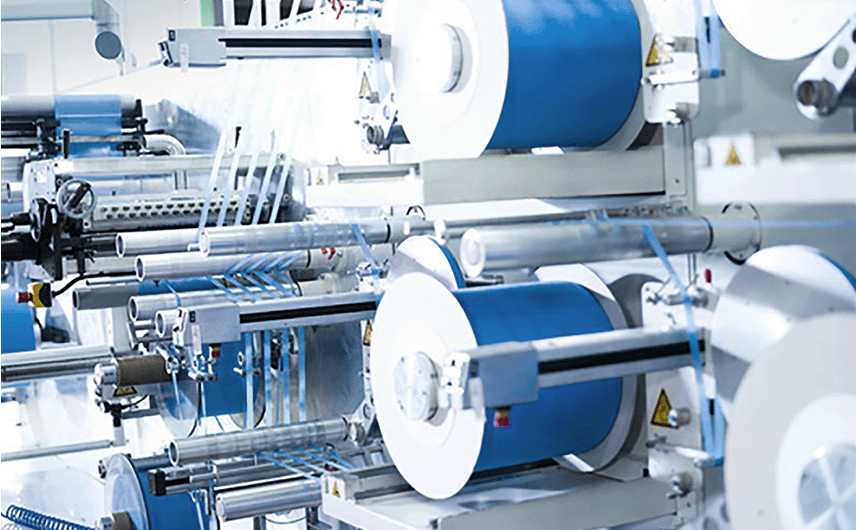

BMM is the central tool that depicts the master data of all extruders or coating machines and manages all maintenance and repair measures. he transparent documentation of the lifecycle file is completed with feedback that provides information about performed measures and answers the question when, who, for how long and what. Up-to-the-minute scheduling of maintenance personnel is performed in a graphic planning table with drag and drop, ensuring efficient usage planning.

Receive our latest newsletters directly to your inbox!