Lean Smart Maintenance with BMM

The Siemens Mobility Austria GmbH in Graz is considered a flagship plant for the LEAN SMART MAINTENANCE philosophy developed by the University of Leoben. A joint cooperation agreement forms the basis for the continuous further development of maintenance and information management. With the BOOM MAINTENANCE MANAGER, the maintenance department has a tool in use, with which the level of excellence can be achieved above all in the following key areas:

Siemens Mobility Graz: Winner of the Maintenance Award Austria 2021

The IPSA system implemented at the Graz location stood out among all the submitted projects. The benefits recognized by the jury include:

A solid order management and the continuous development of strategic elements makes BOOM MAINTENANCE MANAGER a success factor for Siemens Mobility Austria GmbH. For Philipp Hochstrasser (Head of Site Administration Department at Siemens Mobility Austria GmbH) the implemented solution is the foundation for LEAN SMART MAINTENANCE.

Philipp Hochstrasser

Risk-based maintenance as a crucial competitive advantage

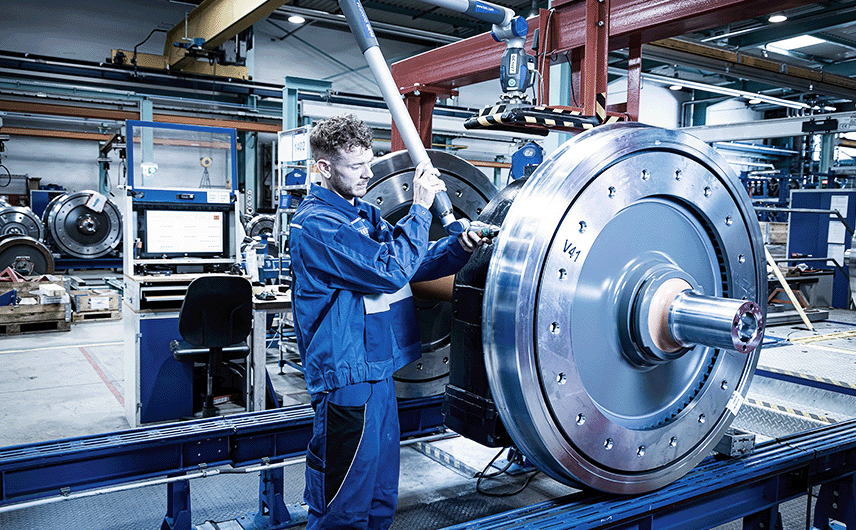

Siemens Mobility GmbH produces technically complex, highly safety-critical products at the World Competence Center for chassis in Graz. Due to the high demands on reliability, availability, maintainability and safety of all components in the system, the identification, evaluation and elimination of risks are among the most important tasks. The CRITICALITY ASSET PRIORITY module is used to determine the criticality of the systems from the perspective of production, work preparation and maintenance. The criticality index helps to reduce gut feeling decisions and to support the decisions made with solid facts. In addition, it promotes transparency by providing comprehensible and well-documented information on the basis of the evaluation for the departments.

Receive our latest newsletters directly to your inbox!