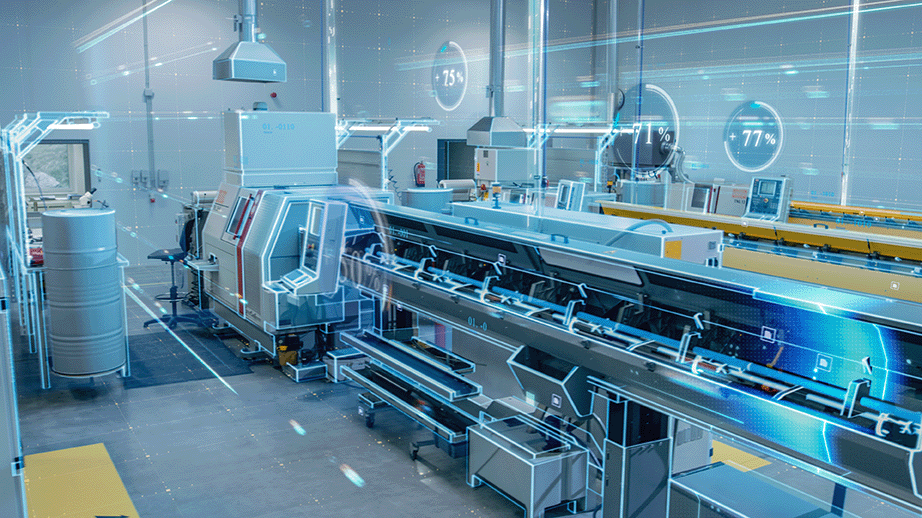

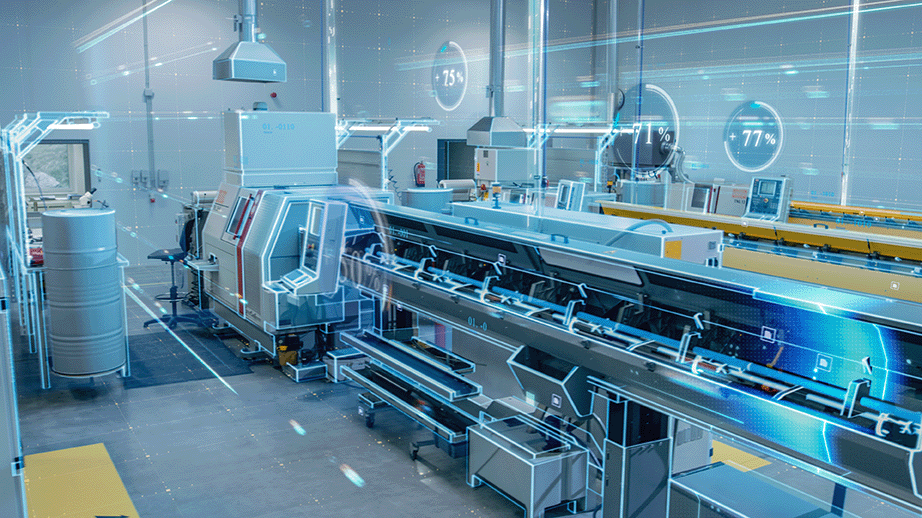

The idea behind Smart Production is to optimize production processes, thereby increasing the efficiency of the operation.

More efficiency: The focus of smart production is on efficiency gains. It is about reducing costs and making better use of the available resources. “Frictional losses” or redundancies, which often become established in a production operation, are also identified more quickly and can be eliminated.

It is precisely in the area of production efficiency that a company or a manufacturing operation can stand out from its competitors.

Improved quality: Monitoring production digitally makes it possible to oversee and improve the quality of products by identifying processes with errors and initiating countermeasures. This results in a strong synergy regarding customer satisfaction, which is improved by increasing quality.

Maximum transparency: Using end-to-end process mapping, it is possible to collect and analyze data and use it for decisions in manufacturing facilities as well as at the corporate level. Weak points, problems, but also potentials can be identified through proper data evaluation. Consequently, it can be ensured that operations run smoothly and efficiently and that products meet requirements. It also ensures transparency between different production and decision-making levels within the company.

"For production companies, Smart Production is often filled with skepticism, especially smaller and medium-sized companies are often hesitant. That's why it's especially important to us not only to adapt our software solutions to the customer, but to develop them together with the customer."

Rene Fabian

Digitalization has the greatest potential when it is considered and successfully applied to the entire production chain.

Boom Software has developed BOOM PRODUCTION MANAGER (BPM), a solution that is tailored to the business and its needs – both for small production companies and complex industrial plants. Boom offers proven software modules that can be individually configured and combined accordingly. Thus. the BPM is capable of maximum adaptability and is independent of business process requirements or technical aspects.

It is crucial for a successful implementation to map the entire cycle: From goods receipt to the finished product leaving the factory. This enables maximum transparency.

By recording and analyzing all relevant data in the production plant, an overview of production is obtained that can be accessed in real time. In addition to automatic reporting, problems and weak points in particular should be quickly identified. Bottlenecks in delivery, quality deficiencies or technical problems with machines are detected at an early stage so that a rapid response can be made. This reduces the error rates in production and thus benefits both in terms of time and money.

However, not only problems are detected, but also potentials and opportunities are to be highlighted by the comprehensive data collection and analysis. This means not only an increase in efficiency in the operating process, but also a business advantage.

High quality standards and reliability are crucial for the greatest possible customer satisfaction. For example, high precision is required in the plastic-, metaland timber industry, which is precisely why Boom Software has focused on these industries.

The BOOM PRODUCTION MANAGER takes over the ongoing analysis of the production process, so conclusions can be drawn about material or product quality. This means that even small deviations from the desired standard are detected immediately and the system alerts the responsible department right away. In this way, production errors or quality defects are averted at an early stage.

Not only the manufacturing plant and the products benefit from Smart Production, but also the environment. Smart Production contributes significantly to improving the sustainability of a production plant. Due to the mindful use of resources as well as the reduction of error rates, production is more efficient resulting in less waste.

In addition, modern technologies such as renewable energies and recycling systems are integrated into the production process, and thus also into smart production management. This contributes to more environmentally friendly production and a reduction in CO2 emissions.

Machines and plants are the heart of a production operation. An unplanned breakdown or defect means not only financial loss, but also an organizational challenge in production planning and logistics.

Smart production involves predictive maintenance. The goal is to collect, store and analyze machine and process data from the plant. The transparency achieved not only involves monitoring the condition of the machines in real time. The targeted identification of weak points and predictions about maintenance and malfunctions are possible. This increases the performance and reliability of the equipment and minimizes unplanned downtime.

The BOOM MAINTENANCE MANAGER (BMM) serves as a central information management system and thus creates the basis for predictive maintenance. In combination with the machine master data and the modules of machine and operating data acquisition, the complete data acquisition or data basis for predictive maintenance is guaranteed.

To best capture and control the complexity of a production facility, it is crucial to link software solutions with existing ERP systems (e.g. SAP). Interfaces enable production-related data to be transferred to and retrieved from the ERP system. This creates a standardized information basis for planning and controlling production. This is another reason why BOOM PRODUCTION MANAGER is always individually adapted to the system landscape in the customer’s plant and thus integrates ideally. In addition, Boom also offers ready-made interfaces to common ERP systems.

Receive our latest newsletters directly to your inbox!